Design. Engineer.

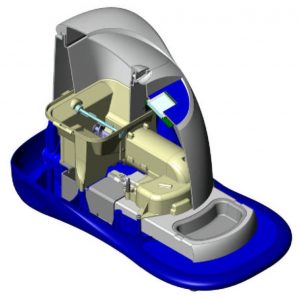

KAP Product Design will design your product creating a 3D CAD model with intelligence and flexibility. Using SolidWorks CAD design tools, part and assembly models will be associative and reflect the design intent crucial to your product’s success. KAP can work as part of your engineering team or independently.

Capabilities include:

-

- Mechanical Design

- Electronic Packaging

- Electro-mechanical Design

- Metal Components

- Plastic Components

- Mechanisms

- Parts and assemblies

- Drafting Services

Electronic Packaging.

Electronic Packaging design includes packaging of chassis, enclosures, mother and daughter board definition, including thermal design and airflow/cooling characteristics.

KAP can assist with printed circuit layout by developing the mechanical definition of the board, connector placements, mounting hole locations and keep out areas. KAP will work with your electrical engineers and PCB layout personnel to achieve a successful design. KAP will develop rack mounted enclosures and custom enclosures; both metal and plastic molded are designed with consideration for EMI/RFI requirements.

KAP can manage your designs ideas using our expertise in manufacturing technologies; surface mount and thru-hole, rigid, flexible and rigid-flex printed circuitry as well as advanced interconnect technologies to create the most cost effective design using the most appropriate manufacturing processes.

Prototyping.

It is often necessary to check, test and evaluate a design. Having a physical model in hand is worth the possibility of finding some undesired features in a design especially in a hand held or consumer device. While a 3D CAD model eliminates many design issues, a physical model allows the client to use and test the product (form, fit, function) prior to committing to production tooling.

Various prototyping methods and materials are available and KAP will recommend the best prototyping method that will satisfy your requirements which are typically performance, cost and schedule. Most prototypes can be made in a few days to a couple of weeks using one of KAP approved partners and made directly from the 3D solid model.

Some of the prototyping methods offered include:

- Stereolithography

- FDM or other 3D printed method

- CNC Machining

- Sheet Metal

- Urethane Castings